Reconditioning

Your Lips-machine needs to be replaced?

You want to improve the safety standards of your machine?

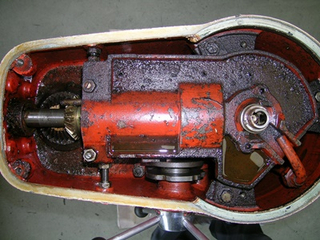

A reconditioned machine is an economical and environmentally friendly alternative to buying a new machine. We recycle your machine instead of disposing it.

The robust iron castings and most other parts of the old machine are used again to rebuild a new, safe food processor, that is better than when it was brand new. Sustainability and quality are guaranteed.

|

| To indicate you which machines can be reconditioned, we created this label. |

The process of reconditioning

First of all it needs to be checked, if the machine is suitable for reconditioning. Please contact us. Maybe we have to do an analysis at your place, but in most cases sending some photos is enough.

The old machine needs to be brought to the factory at Uetendorf (Switzerland), where our specialists are waiting for the machine.

If you are unable to work without your Lips-machine during the period of the revision, we have spare machines at your disposal. Further there is the possibility of exchanging the machine, we get your old machine and we give you a perfectly reconditioned machine. In that case we charge you the costs of an average reconditioning.

Work steps

The following work steps are executed:

Warranty

We grant 2 years warranty on the revised machine starting at the date of delivery. Otherwise our General Conditions of Sale and Delivery apply.

If You have any questions about factory revisions please ask our costumer service.